interchangeable parts

description: components that are identical for practical purposes

137 results

The Perfectionists: How Precision Engineers Created the Modern World

by

Simon Winchester

Published 7 May 2018

Scott, The Crack-Up, 307 fixtures (devices that hold workpiece absolutely secure), 100n, 102 flatness: of surface plates, 75–76, 119–20 of Whitworth’s billiard table, 124–25 flintlocks, see muskets, flintlock flour-milling machinery, 102 f number of lens, 219n Ford, Henry, 129, 131, 155–67, 157, 276 altruistic motives of, 155–56 early years of, 156–58 first motor car experiments of, 158–59 gauge blocks, or Jo blocks, utilized by, 169–71 mass production assembly line created by, 160–67 Royce compared to, 131, 155–56, 158–59, 165–66 Westinghouse threshing engines in origin story of, 156–58 Ford Foundation, 166 Ford Model T (Tin Lizzie), 129, 155–56, 157, 160–67 decreases in price of, 165, 167 magneto assembly for, 164–65 production line for, 160–67 Ford Motor Company, 152, 155–67 complaints about SKF bearings at, 170 Edsel, 236 gauge blocks, or Jo blocks, introduced at, 169–71 incorporation of, 131, 159 interchangeable parts essential at, 161n, 166, 170 Model A, 159–60 Model T, see Ford Model T (Tin Lizzie) precision’s role at Rolls-Royce vs., 131, 166–67 production line at, 160–65 “For want of a nail . . .” proverb, 244 foundries, electronic, 278n fountain pens, 58 France: Anglo-French rivalry over inventions and, 87n automobiles made in, 137–39 British wars with, 39n, 66, 73 decimal time in, 349n postrevolutionary Republican Calendar in, 333–34 social implications of precision as concern in, 90, 92, 117 standards for length and mass created by, 334–40; see also metric system system of interchangeable parts developed in, 87–94, 97, 98, 102 Franklin, Benjamin, 90, 222–23 French Academy of Sciences, 335 French Revolution, 59, 66, 92 frequency: Doppler effect and, 260–61 units of measurement and, 347–48 friction problem, in early clocks, 32–33, 35 Gainsborough, Thomas, 38–39 Galileo, 222, 332, 348 Galileo global navigation system, 270 Gascoigne, William, 77 Gaudy Night, 105 gauge blocks, or Jo blocks, 167–71, 169 author’s introduction to, 2–4 Ford Motor Company and, 169–71 interchangeable parts and, 170 Johansson’s invention of, 167–68 gauges: go and no-go, for ensuring cannonball fit, 87 in gun manufacture, 89, 98–99, 100 gearwheels: from Ancient Greece (Antikythera mechanism), 24–27 producing, 4–5 uses for, 5–6 wooden, in Harrison’s clocks, 32–33 Gee, 259, 262 George III, King, 36, 74n George VI, King, 194–95 Germany, turbojet-powered aircraft developed by, 179, 184, 190–91, 195 Gernsback, Hugo, 181 glassblowers, scientific, 7 Glass Menagerie, The (Williams), 255 Global Positioning System (GPS), 37, 265–74 Doppler-based navigation system as precursor of, 259–65, 267 Easton’s invention of, 260, 265–68 ever-more-precise calculations of, 272–73 freed for civilian use, 269–70 major achievements of nineteenth-century cartography checked against data from, 273n military uses of, 269 other nations’ similar systems, 270 Parkinson’s vision for, 267–68, 268 run from tightly guarded Schriever Air Force Base, 270–72, 271, 272 time data for, 352–53 GLONASS, 270 Gloster Aircraft Company: experimental aircraft powered by jet engine (Gloster E28/29, or Pioneer), 190, 191–94 Gloster Meteor fighters, 192 Goddard Space Flight Center (Maryland), 234, 250–51, 294 Gould, Rupert, 34n graphene, 298 grasshopper escapement, 33 gravitational constant, 298 gravitational waves, detection of, 20–21, 300–306 see also LIGO (Laser Interferometer Gravitational-Wave Observatory) gravity: Bramah’s lock design and, 57 clock mechanisms and, 33, 354 link between time and, 354–55 pendulum swings and, 33, 333, 349 Whitworth’s measuring machine and, 121, 122 Great Britain: Anglo-French rivalry over inventions and, 87n divergent paths of industry in U.S. vs., 114–15 trading fortunes and, 31 War of 1812 and, 81–85 wars fought by, in eighteenth and early nineteenth centuries, 39, 66–71 Great Exhibition of the Works of Industry of All Nations (London, 1851), 111–27, 112 arrangement of exhibits at, 115–16 Bramah’s “challenge lock” picked at, 112n, 124, 125–27 Crystal Palace built for, 112, 113–14 extraordinary zeitgeist of the time and, 111–13 financing of, 113 great big iron machines displayed at, 114–16, 117–18 Hunt’s concern about social implications of machines displayed at, 116–17 origin of idea for, 112–13n Whitworth’s instruments and tools displayed at, 118–23 Great Trigonometric Survey of India, 273n Greece, Ancient: astronomers from, 26n gearwheels from (Antikythera mechanism), 24–27, 36 lost-wax method in, 204 measurement of time in, 27 Greenwich Royal Observatory, Harrison’s clocks at, 30–37 restoration of, 34n winding of, 30–31 Gribeauval, Jean-Baptiste Vaquette de, 87, 89, 92, 98 Guier, William, 259–62 Gulf War of 1991, 269 guns: Blanchard’s lathe for stocks of, 101–2 both precision and accuracy crucial in making of, 105 breech-loaded single-shot rifles, 97–98 French system of interchangeable parts applied to American precision-based manufacturing of, 97–100 Johansson’s invention of gauge blocks, or Jo blocks, and, 167–68 machines first used to make components of, 98, 99–100 rudiments of mass production assembly lines in manufacture of, 161n Victoria’s opening shot in 1860 Grand Rifle Match, 107–10 see also muskets, flintlock Hall, Bishop Joseph, Works, 331 Hall, John, 97–98, 99–100, 102 handcrafting: Antikythera mechanism and, 24–25, 27 Blanc’s standardization system and, 89–90, 92, 98 eliminated in Ford’s assembly line, 165, 166–67 Japanese appreciation for, 308, 309–10, 314, 316, 319–29 machine tools vs., 35, 38, 60, 72–73, 98–99 at Rolls-Royce, 6, 131, 152–55, 165, 166 social consequences of move away from, 72–75, 89–90, 116–17 and survival of craftsmanship in France, 92 in Whitney’s gun factory, 96–97 Hanford, Wash., cleanup site, 19–20 Harpers Ferry Armory (Va.), 98, 99, 102, 161n Harrison, John, 24, 30–37, 47, 67, 105, 267n balance mechanisms in clocks made by, 33, 35 Board of Longitude prize and, 30, 31, 32, 34, 35–36 large pendulum clocks made by (H1, H2, and H3), 30–31, 32–34, 35 restoration of clocks made by, 34n sea watches made by (H4 and K1), 31–32, 34–36 testing of clocks made by, 34, 35–36, 39 winding of clocks made by, 30–31, 33, 35 Harrison, William, 35–36 Hattori, K., and Company, 311–13 Hattori, Kintaro, 310–12 Heinkel Company, 184, 195 Heinkel He 178, 190–91 Heisenberg, Werner, 212–13, 298 Die Physik der Atomkerne, 275 Herbert, George, 244n Herschel family (William, Caroline, John, and Alexander), 229–30n Hiroshima, atomic bomb dropped on, 281 Hitler, Adolf, 187, 191 Hobbs, Alfred C., 124, 125–27 Hoerni, Jean Amédée, 284–85, 286n, 287 Hooker, Sir Stanley, 139 hour: defining, 28, 334, 349 displayed by mechanical clocks, 28–29 Hubble, Edwin, 2321 Hubble Space Telescope, 229–53, 230 cost of, 232 delays in launch date of, 243n first images from (First Light), 234–35, 251 flaw in main mirror of, 234, 234–43; see also Perkin-Elmer Corporation High Speed Photometer in, 247, 248, 250 money matters and, 237n news of failure announced to press, 235–36 placed into orbit, 230–32, 233 public reverence for, 229–30 repair of, 244–51 second images from (Second Light), 251–52 size and appearance of, 232–33 teacup affair and, 238 ultimate success of, 252–53 Wide Field and Planetary Camera in (Wiffpic), 247–48, 249 Hucknall Casings and Structures plant (Rolls-Royce), 209–10, 211, 229 Hunt, Robert, 116–17 hydraulic press, 57–58 India, Great Trigonometric Survey of, 273n Individual and the Universe, The (Lovell), 215 Industrial Revolution, 39, 41, 44, 51, 73, 74n, 111, 304 integrated circuitry, 286–99 devices made possible by, 287–88 Noyce’s work in genesis of, 286, 287, 288n printing with photolithographic machines, 277, 277–78, 286–87, 294 see also microprocessor chips; transisters Intel, 288–92 ASML machines bought by, 275–76, 277, 277–78 Chandler, Ariz., fabrication plant of (Fab 42), 275–76, 277–78, 291–92 first-ever commercially available microprocessor made by (Intel 4004), 288–89, 290, 292 founding of, 288 mutual dependency of ASML and, 278 interchangeable parts, 63, 71, 105, 114, 276, 312 in Ford’s mass production assembly lines, 161n, 166, 170 for guns, 84–85, 86, 87–100 system of, developed in France, 87–94, 97, 98, 102 interferometers: classic, 300 laser, 242–43 LIGO (Laser Interferometer Gravitational-Wave Observatory), 20–21, 299–306, 303, 305 null connector as, 240–41 internal combustion engine, 158 aircraft powered by, 178–213; see also jet engines International Astronomical Union, 344 International Committee on Weights and Measures (1960), 345–46 International Metre Commission (1872), 338 International Prototype Kilogram (IPK), 339 International Prototype Meter (IPM), 339 International System of Units (SI), 16–17n, 346 iron, 38, 39 cannon making and, 39, 41–44 Japanese handcrafted objects made of, 309–10 lathes made of, rather than wood, 61, 64 machines to manufacture pulley blocks made of, 71 smelting and forging, 40–41, 43, 49 steam engines made of, 46, 48–52 Wilkinson’s cylinder-boring technique for, 42–44, 49–52, 304–6 Iron Bridge of Coalbrookdale, 41 Ito, Tsutomi, 321–22 Jacula Prudentum, 244n James Webb Space Telescope, 231n, 294, 295, 299 Janety, Marc Étienne, 336, 337 Japan, 308–29 bamboo objects handcrafted in, 325, 326 fondness for handcrafting in, 308, 309–10, 314, 316, 319–29 Great Tohoku Earthquake and Tsunami in (2011), 322, 323–25 Living National Treasures of, 325–26 rigorous appreciation of perfect in, 308–9, 314 timekeeping traditions in, 310–11 urushi (handmade lacquerware) of, 326–28, 327 Westernization in, 310, 311 see also Seiko Japanese Railways, 313–14 Jay, John, 92–93 Jefferson, Thomas, 52 Blanc’s flintlock system and, 90, 92–94, 96 Whitney’s contract and demonstration and, 95, 96 Jet Age, inauguration of, 193 jet engines, 173–213 alloys for blades in, 200, 201, 203 Americans’ initial lack of interest in, 179 bird strikes and, 203n British public told of, 194 complexity within, 196–97 experimental aircraft fitted with, 190, 191–94 financial backing for development of, 184–85, 189 first passenger and freight aircraft with, 198–99 French forerunner of, 179 German development of, 179, 184, 190–91, 195 hot environment in, 187, 199–201 invention of, 178–94, 179; see also Whittle, Frank keeping blades cool inside, 197–98, 198, 199–203, 204, 206 manufacturing process for single-crystal blades in, 203–6 no tolerance whatsoever in making of, 206–7 power of piston engine vs., 182–83 propulsive jet of air produced by, 182, 187 Quantas Flight 32 and failure of, 174–78, 178, 196, 207–12, 208, 229 revolutionary novelty of idea for, 186 Rolls-Royce, 196–213, 205; see also Rolls-Royce jet engines single moving part in, 180 stress of takeoff and landing cycles on, 210 testing of prototypes, 187–90 turbine blade efficiency and, 198 Whittle’s eureka moment and, 182–83 Whittle’s patent and, 183–84 Jet Propulsion Laboratory, or JPL (Pasadena), 247–48, 350 Jo blocks, see gauge blocks, or Jo blocks Johansson, Carl Edvard, 3, 167–71 bought out by Ford, 170–71 gauge blocks, or Jo blocks, created by, 167–68 Johns Hopkins University: Applied Physics Laboratory (APL) at, 259–62 Space Telescope Science Institute at, 234, 251 Johnson, Claude “CJ,” 148–50, 151 Jones, Alexander, 27 Kai Tak Airport (Hong Kong), 195–96 kelvin, definition of, 346 Kiev, author photographed with Rolls-Royce outside city gates of, 133–34 Kilby, Jack, 288n kilogram, 336–40, 346–47 cast in platinum as étalon (standard), 337, 339–40, 348 now defined in terms of speed of light, 348 relationship of meter to, 336–37 see also metric system Kilogram of the Archives, 336 Klein bottle, 7n Kodak, 237n Korean Air Lines Flight 007, shooting down of, 269 krypton, standard unit of length based on, 344–45 Kyoto, temples of, 308 landscape photography, lenses for, 226 lasers, 351 in LIGO’s measuring instrument, 301, 305, 305–6 in manufacture of microprocessor chips, 293–94, 296 presumed to be precise, 242 lathes, 61–65 for gun stocks, designed by Blanchard, 101–2 invention and evolution of, 61 iron vs. wood, 61, 64 Maudslay’s improvements to, 61–65 screw-making, 63–64 for shoe lasts, designed by Blanchard, 19n, 101 slide rest and, 62–63, 64–65 latitude, determining, 30n leadscrews: of bench micrometers, 77–78 of lathes, 61, 62–63 Leica, 221, 222, 227–28 cameras owned by author, 219–20 lenses made by, 220, 224–25, 227–28 Leitz, Ernst, 222, 227 Leland, Henry, 168 length, standard unit of, 334–40 cast in platinum as étalon (standard), 336, 337, 339–40 mass in relation to, 336–37 meridian of Earth and, 334–36, 337 now defined in terms of time, 348 pendulum swing and, 332–33 redefined as wavelength of light, 342–45 Wilkins’s proposal for, 332–33 see also metric system Lenin, V.

…

Crucial to all these industries, and absolutely crucial in Henry Ford’s new automobile-manufacturing industry, was the use of interchangeable parts. It is worth noting that none of Ford’s early-model cars (the A, B, C, F, K, or N) relied entirely on its components’ interchangeability. But the Model T did, and did so in spades. Some claim that Ransom Olds was the industrialist who pioneered the use of assembly lines in the making of cars, but he managed to make industrial history confusing by not using interchangeable parts—the workers on his Oldsmobile assembly lines still filed metal pieces to make them fit. * As well as the Lincoln—and the electric starter motor, which he built after his best friend was knocked out and killed by the unexpected kickback of a large car’s starting crank

…

Metal pieces can be machined into a range of shapes and sizes and configurations, and provided that the settings of the leadscrew and the slide rest are the same for every procedure, and the lathe operator can record these positions and make certain they are the same, time after time, then every machined piece will be the same—will look the same, measure the same, weigh the same (if of the same density of metal) as every other. The pieces are all replicable. They are, crucially, interchangeable. If the machined pieces are to be the parts of a further machine—if they are gearwheels, say, or triggers, or handgrips, or barrels—then they will be interchangeable parts, the ultimate cornerstone components of modern manufacturing. Of equally fundamental importance, a lathe so abundantly equipped as Maudslay’s was also able to make that most essential component of the industrialized world, the screw. Over the centuries, there were many incremental advances in screw making, as we shall see, but it was Henry Maudslay (once he had invented or mastered or improved or in some other manner become intimately associated with the slide rest on his lathe) who then devised a means of cutting metal screws, efficiently, precisely, and fast.

The Connected Company

by

Dave Gray

and

Thomas Vander Wal

Published 2 Dec 2014

Logitech (company), Net Promoter at Logitech–Net Promoter at Logitech, Net Promoter at Logitech loose coupling, Service Contracts, Loose Coupling, Most Companies are Not Built for Agility about, Service Contracts, Loose Coupling car example, Most Companies are Not Built for Agility Lusch, Robert F., Service-Dominant Logic M machines, The Company as a Machine–Closed and Open Systems, The Company as a Machine, The Company as a Machine, Closed and Open Systems, Closed and Open Systems, Closed and Open Systems as closed systems, Closed and Open Systems companies as, The Company as a Machine–Closed and Open Systems, The Company as a Machine, Closed and Open Systems, Closed and Open Systems purpose of, The Company as a Machine Mackey, John, It Takes Trust to Build Relationships Mailchimp (company), Strategy by Discovery management, Leading from the Edge, Managing the connected company, Management is a Support System, Designing the System–Rely on Peer-to-Peer Reinforcement Whenever Possible, Balance the Individual Freedom with the Common Good, Build Slack into Central Resources to Ensure Availability, Rely on Peer-to-Peer Reinforcement Whenever Possible, Rely on Peer-to-Peer Reinforcement Whenever Possible, Operating the System, Critical Values in Complex Adaptive Systems, Symptoms, Tuning the System–The Job of Managers, Tuning the System, Information Transparency, Density, Rate of Flow, Structural Change, The Job of Managers, The Job of Managers, The Job of Managers as support system, Management is a Support System designing system for, Designing the System–Rely on Peer-to-Peer Reinforcement Whenever Possible, Balance the Individual Freedom with the Common Good, Build Slack into Central Resources to Ensure Availability, Rely on Peer-to-Peer Reinforcement Whenever Possible, Rely on Peer-to-Peer Reinforcement Whenever Possible leadership versus, Leading from the Edge operating the system, Operating the System, Critical Values in Complex Adaptive Systems, Symptoms, Tuning the System purpose of, Managing the connected company role of, The Job of Managers tuning the system, Tuning the System–The Job of Managers, Information Transparency, Density, Rate of Flow, Structural Change, The Job of Managers, The Job of Managers maneuver warfare, Three Types of Strategy Marriott International, Connecting an Internal Group at Marriott–Connecting an Internal Group at Marriott, Connecting an Internal Group at Marriott mass marketing, product saturation and, An Age of Abundance–An Age of Abundance, An Age of Abundance, An Age of Abundance mass production, Interchangeable Parts–Conflicting Constraints Lead to Rigidity, Interchangeable Parts, Conflicting Constraints Lead to Rigidity standardization and, Interchangeable Parts–Conflicting Constraints Lead to Rigidity, Interchangeable Parts, Conflicting Constraints Lead to Rigidity Maverick (Semler), Democratic Management at Semco McCarthy, Patrick D., Freedom to Experiment, The Nordstrom Way McDonald’s (company), Reducing Variety–Absorbing Variety, Reducing Variety, Absorbing Variety, Support–Balancing the Needs of Constituents, Balancing the Needs of Constituents reducing variety, Reducing Variety–Absorbing Variety, Reducing Variety, Absorbing Variety support structure, Support–Balancing the Needs of Constituents, Balancing the Needs of Constituents McIntyre, Tim, Cascading Effects Can be Initiated by Employees McKelvey, Bill, The Red Queen Race, Adaptive Tensions Microsoft Corporation, What is a Platform?

…

Smith, Adam, Dividing Work, Attractors Smith, Greg, Failure of Purpose SOA (Service-Oriented Architecture), Standards Sony, Purpose Sets the Context for Organizations to Learn, Over-Controlling the Platform SOPA (Stop Online Privacy Act), Adaptive Moves Can Create Opportunities for Others Southwest Airlines, Balancing Promise, Purpose, and Performance, Freedom to Experiment, Not Enough Autonomy Spector, Robert, Freedom to Experiment, The Nordstrom Way standards and standardization, Interchangeable Parts–Conflicting Constraints Lead to Rigidity, Conflicting Constraints Lead to Rigidity, Reducing Variety, Reducing Variety, Loose Coupling customers resisting, Reducing Variety interchangeable parts, Interchangeable Parts–Conflicting Constraints Lead to Rigidity, Conflicting Constraints Lead to Rigidity loose coupling and, Loose Coupling reducing variety by, Reducing Variety Starbucks (company), A Wake-up Call at Starbucks, A Wake-up Call at Starbucks, Something’s Happening Here, Control confidential memo leak, A Wake-up Call at Starbucks, A Wake-up Call at Starbucks, Something’s Happening Here, Control Starkweather, Gary, How Xerox Missed the PC Revolution State Department, Power in the Network Stop Online Privacy Act (SOPA),, Adaptive Moves Can Create Opportunities for Others strategy, Let a Thousand Flowers Bloom, Let a Thousand Flowers Bloom–A Portfolio of Experiments, Let a Thousand Flowers Bloom, Let a Thousand Flowers Bloom, A Portfolio of Experiments–Be Connectable to Everything, A Portfolio of Experiments, Big Bets: The Responsibility of Senior Leaders, Big Bets: The Responsibility of Senior Leaders–Be Connectable to Everything, Be Connectable to Everything, Be Connectable to Everything, Strategy by Discovery, Strategy by Discovery–Strategy by Discovery, Strategy by Discovery, Strategy by Discovery, Strategy by Discovery, Leading from the Edge–People First, People First, People First, Moral Authority being connectable, Big Bets: The Responsibility of Senior Leaders–Be Connectable to Everything, Be Connectable to Everything by discovery, Strategy by Discovery–Strategy by Discovery, Strategy by Discovery, Strategy by Discovery deliberate, Let a Thousand Flowers Bloom–A Portfolio of Experiments, A Portfolio of Experiments emergent, Let a Thousand Flowers Bloom, Let a Thousand Flowers Bloom, Strategy by Discovery, Strategy by Discovery evolving nature of, Let a Thousand Flowers Bloom for leading connected companies, Leading from the Edge–People First, People First, People First Golden Rule, Moral Authority portfolio of experiments, A Portfolio of Experiments–Be Connectable to Everything, Big Bets: The Responsibility of Senior Leaders, Be Connectable to Everything strategy decay, Strategies Don’t Last Forever strong ties, Small Worlds structural change, Structural change is necessary–Conflicting Constraints Lead to Rigidity, Conflicting Constraints Lead to Rigidity, Conflicting Constraints Lead to Rigidity, Conflicting Constraints Lead to Rigidity, Conflicting Constraints Lead to Rigidity successive approximation process, The Growth Spiral systems of systems, The Complexity Issue T Tabas, Lindsay, Balancing the Front Stage and the Back Stage tacit knowledge, Tacit and Explicit Knowledge–Learning Fields, Tacit and Explicit Knowledge, Learning Fields Target (retail stores), Every Adaptive Move by One Organization Affects Others, Net Promoter at Apple Taylor, Andy, Net Promoter at Enterprise Taylor, Bob, Cascading Effects Can be Initiated by Customers Taylor, Frederick, The Company as a Machine TED Airline, Not Enough Autonomy temperature of companies, Critical Values in Complex Adaptive Systems–Symptoms, Symptoms, Symptoms Tesler, Larry, How Xerox Missed the PC Revolution The Boy Genius Report blog, Cascading Effects Can be Initiated by Senior Executives The Elastic Enterprise (Vitari and Shaughnessy), Be Connectable to Everything The Future of Management (Hamel), Diversity Matters, It Won’t be Easy The Ghost in the Machine (Koestler), The Parable of the Watchmakers The Great Reset (Florida), The Great Reset The Living Company (de Geus), The Long-lived Company The Nordstrom Way (Spector and McCarthy), Freedom to Experiment, The Nordstrom Way The Origin of Wealth (Beinhocker), Let a Thousand Flowers Bloom The Power of Pull (Hagel and Brown), Return on Assets is Dwindling The Service Profit Chain (Heskett and Sasser), Purpose Sets the Context for Organizations to Learn, Too Much Autonomy The Seven-Day Weekend (Semler), Democratic Management at Semco The Ultimate Question (Reichheld), How Profits Can Destroy Your Company Thelonious Monk Institute of Jazz, Cascading Effects Can be Initiated by Customers Thompson, Gav, Disrupting Full-Service Telecom at O2 thou shalt not platform, Governance tight coupling, Service Contracts, Most Companies are Not Built for Agility about, Service Contracts train on track example, Most Companies are Not Built for Agility tipping point, We are Reaching a Complexity Tipping Point, Strategy by Discovery, Build Slack into Central Resources to Ensure Availability for complexity, We are Reaching a Complexity Tipping Point for emergent strategy, Strategy by Discovery for utilization of resources, Build Slack into Central Resources to Ensure Availability top-down, leader-driven change, Top-Down, Leader-Driven Change–Launch a Pilot Pod to Shift to a New Business Model, Top-Down, Leader-Driven Change, Common Threads, Pilot Pods, Launch a Pilot Pod to Shift to a New Business Model Torvalds, Linus, What is a Platform?

…

In addition, although dividing work may make the system more efficient, by dividing work into ever-more specialized tasks, we also disconnect people from the meaning and purpose of what they are doing. From their small, constrained box, people can’t see the big picture, so they must make decisions and act with a very limited perspective. Interchangeable Parts Another core idea from the age of the industrial revolution is the concept of interchangeable parts. Standardization does make it easier to mass-produce quality products. We run into problems, though, when we try to apply standards to things that inherently have a high degree of variety—for example, a customer service call. Customer problems come in all shapes and sizes, and even problems that might seem very similar on the surface can be subject to a lot of variability based on the context.

The Dawn of Innovation: The First American Industrial Revolution

by

Charles R. Morris

Published 1 Jan 2012

According to the traditional story, Whitney was the inventor of the cotton gin, which transformed the antebellum South (and unfortunately reinvigorated the institution of slavery); he was the first person to machine-produce precisely fitting interchangeable parts for muskets and was the inventor of critical new machine tools, like the celebrated Whitney milling machine. The Whitney role in military manufacturing came under withering challenge in the 1960s. The revisionists charged that Whitney’s pretension to making arms with interchangeable parts was merely a ploy to justify extensions of his contracts. Indeed, he had little idea of how to manufacture muskets at all, much less how to blaze new trails in making them.

…

While it’s true that Whitney made few contributions to machining technology, most of the extreme claims for his accomplishments were made by others, often long after his death. The traditional source for the story that he claimed to manufacture interchangeable parts appears to be itself a partial fabrication.6 While he did have a rocky start on his first musket contract, so did many other contractors. The current consensus is that Whitney was quite a competent manufacturer and one of the earliest advocates for mass production by machinery, if not expressly for interchangeable parts—in short, a respectable figure, if not the demigod of legend. My own view is that in his early career Whitney was indeed something of a flimflam man; some recent work even raises doubts as to whether he invented his cotton gin (see Appendix).

…

My own view is that in his early career Whitney was indeed something of a flimflam man; some recent work even raises doubts as to whether he invented his cotton gin (see Appendix). And I think the record supports the charge that he dangled the promise of machined interchangeable parts to gain extensions on his contracts. But it’s also true that he was a talented artisan and entrepreneur, and once he focused on actually building his weapons—about 1805, when he turned forty—he proved himself to be a good manufacturer and was regarded as such by his peers and armory officials. While it is almost impossible to trace weapon types to specific battles, there is decent circumstantial evidence that Whitney’s muskets were used by a good portion of the troops in some of the hottest infantry engagements of the War of 1812 and that they performed as expected.

Empire of Guns

by

Priya Satia

Published 10 Apr 2018

In 1813, the Connecticut contractor Simeon North made pistol locks with interchangeable parts, and in 1815 the Ordnance Department acquired the teeth to implement uniformity as a general objective. It took time, however, not least because of resistance from artisans at Harpers Ferry. In 1819, the Harpers Ferry gunsmith John Hancock Hall contracted to make a breech-loading rifle he had patented in 1811. He used dozens of gauges and much machinery, showing definitively, in 1826, that his rifles could be made with interchangeable parts—the first of their kind. Legally, arms for militias had to be made by contractors, so the War Department had Hall share his technology with North.

…

The revolutionary French government launched the Manufacture of Paris, which employed more than five thousand at its peak in thirty government-run workshops—the largest ever “crash” industrial project in Europe, aiming to produce a thousand muskets a day, six times the combined output of the ancien regime’s three armories. Uncompromising Enlightenment-minded engineers insisted on interchangeable parts production on principle, in the face of opposition from artisanal gunsmiths and arms merchants. After a year, the governing National Convention closed it, reestablishing the ancien regime “amalgam of private capitalism and statist direction.” In 1794, the Spanish government also established a factory in Oviedo, which would average more than eight hundred muskets per month by 1798.

…

At that point, thousands of guns were ordered from contractors, and construction at Harpers Ferry began. It produced its first arms in 1800, although production became regular only around 1808. Its first superintendent was a Birmingham gunsmith who maintained European-style craft practices, employing individual artisans to manufacture each part. The goal of interchangeable parts was adopted from French military traditions and guided developments, but it took time. The British government’s factory plan stalled until 1805, partly to avoid drawing artisans away from the contractors’ work in a desperate time. In the meantime, the Ordnance Office turned Birmingham itself into something of a factory.

The Technology Trap: Capital, Labor, and Power in the Age of Automation

by

Carl Benedikt Frey

Published 17 Jun 2019

Eli Whitney, Samuel Colt, Isaac Singer, and Cyrus McCormick are often viewed as the pioneers of the so-called American system of manufacturing, in which complex products are assembled from mass-produced individual and interchangeable parts. The superiority of this system was widely recognized during the 1851 Crystal Palace Exhibition in London. As one visitor observed, “Nearly all American machines did things that the world earnestly wished machines to do.… Most exciting was Samuel Colt’s repeat-action revolver, which was not only marvelously lethal but made from interchangeable parts, a method so distinctive that it became known as the American system.”7 Yet the concept of interchangeable parts was not an American invention, if it can be regarded an invention at all.

…

See also Industrial Revolution Bronx, 182 Bronx-Whitestone Bridge, 167 Bronze Age, 35 Brown, Sherrod, 291 Brynjolfsson, Erik, 303, 326, 329, 339 bubonic plague (1348) (Black Death), 67, 75 Bureau of Labor Statistics (BLS), 191 Bush, George W., 357 Bythell, Duncan, 121 California Civil Code of 1872, 359 Čapek, Karel, 74 capitalism: perceived threat to, 210; beginnings of, 70; criticism of, 342; impact of clocks on evolution of, 47; rise of, 218; Jeffersonian ideal under, 212; normal state of, 210 capitalist achievement, 294 Capitoline Hill, 40 Captain Swing riots, 130, 285 caravel construction, 50–51 Cardwell, Donald, 47, 59, 97 Carlyle, Thomas, 117 Carnegie, Andrew, 208 Cartwright, Edmund, 105, 127 Case, Anne, 255–56 Cave, Edward, 102 Celestine III, Pope, 44 cement masonry, discovery of, 37 Chadwick, Edwin, 114–15 Charles I of England, King, 54–55, 82, 86 Chartism, 137 cheap labor, slower mechanization and, 75 Cherlin, Andrew, 276, 279 Chetty, Raj, 253, 361 child labor, 103, 123, 134; as opportunity cost to education, 214; robots of Industrial Revolution, 8–9 chimney aristocracy, 89 China: admission to World Trade Organization, 281, 286; ascent of, 289; delayed industrialization in, 88; trade war with, 331 Christensen, Clayton, 354 Chrysler Building, 182 civil rights: lagging, 20; legislation, 280 Civil War (American), 75 Civil War (English), 81 Clark, Gregory, 29, 48, 60 classical civilizations, 37 clientelism, 271 Clinton, Hillary, 285 clocks, 47 Coalbrookdale Iron Company, 108 cognitive divide, 238–43 Colbert, Jean-Baptiste, 84 collective action problem, 19–20 collective bargaining, 192 college-educated citizens: activities of, 352; detachment of, 256; among Great Divergence, 258, 358; hours per day worked, 338; perceived untrustworthiness of, 278; promotion of, 350; qualified as middle class, 239 Colt, Samuel, 149–50 Columbus, Christopher, 51, 67 Communist Manifesto, 7, 63, 70, 119 competition: among nation-states, 19, 57, 89; cascading, 289 computer-aided design software, 13 computer-controlled machines, jobs eliminated by, 228 computer publishing, 247 computers: age of, 228–38; analysts in, 235; automation anxiety concerning, 183; jobs created in, 16; ranks of the affluent in, 224; revolution, 249; those who thrived in, 16; trend beginning with, 258 connectivity, 362–63 consumer products: cheapening of, 294; new, Americans’ growing appetite for, 203 containerization, 171–72 Corbyn, Jeremy, 281 Corn Laws, 267 corporate giants, 208 corporate paternalism, 200 corporate profits, 132, 244 cotton cloth guild, 88 cotton industry, 100 cotton production, mechanization of, 7 Cowie, Jefferson, 200 craft guilds, 55–57, 87 Crafts, Nicholas, 107, 329 crime, joblessness and, 253 Crimean War, 150 Crompton, Samuel, 94, 102 Crouzet, François, 70 Crystal Palace Exhibition of 1851, 147, 149 cultural phenomenon, working class as, 278 culture of growth, 77 Dactyl, 313 Da Gama, Vasco, 51, 67 Dahl, Robert, 273, 352 Daimler, Gottlieb, 166 Darby, Abraham, 108 Dark Ages, light in, 41–51 data, as the new oil, 304 David, Paul, 153, 326 Davis, James J., 175 “deaths of despair,” 256 Deaton, Angus, 8, 255 Declaration of Rights of 1689 (Bill of Rights), 79 Decree Tractor Company, 215 Deep Blue, 303 deep learning, 304 Deep Mind, 301 Defense Advanced Research Projects Agency (DARPA), 307 Defoe, Daniel, 68–69, 71, 84 democracy: legitimacy of, undermining of, 274; liberal, components of, 267; middle class and, 265–69; rise of, 265 Descartes, René, 94 Detroit, Michigan, 151, 257, 359 Devine, Warren, Jr., 153 Diamond, Jared, 64 Dickens, Charles, 117 digital communication, 360 digital industries, clustering of, 260 Diocletian, Roman Emperor, 65 disappearance of jobs, 250–52 “disciplined self” identity, 279 Disraeli, Benjamin, 112, 268 Dittmar, Jeremiah, 48 Domesday Book of 1086, 44 domestic system of production, 61, 71; downfall of, 8 Douglas, Paul H., 178–79 Drebbel, Cornelis, 52 drones, 342 Drucker, Peter F., 227 drudgery, end of, 193–98 Dust Bowl (1930s), 193, 204 Dutch Revolt, 81 Earned Income Tax Credit (EITC), 357 earnings gap, 230 economic incentive, lack of, 40 economic inequality, 22, 274, 277 economic parasites, 79 economic segregation, 356 economies of scale, factories taking advantage of, 110 Eden, Frederick, 116, 344 Edison, Thomas, 2, 52, 148, 189 education and technology, race between, 216 Eilmer of Malmesbury, 78 Eisenhower, Dwight, 307 electricity, early days of, 151 electrification, rural, 157 Electronic Numerical Integrator and Calculator (ENIAC), 230 elevator: arrival of, 14; automatic, 182 Elevator Industry Association, 182 elevator operators, vanishing of, 181, 227 Elizabeth I of England, Queen, 10, 54, 105 Empire State Building, 182 enabling technologies, 13, 227, 228 Engels, Friedrich, 70, 112, 249, 364 Engels’ pause, 131–37, 219; ending of, 287; polarization and, 266; return of, 243–48, 331; time of, 337 English craft guilds, fading power of, 87 entrepreneurial risk, 77 Facebook, 285 factory system, 8, 97, 126; annus mirabilis of 1769, 97; artisans, 98; child labor, 103, 104; coke smelting, 109; control over factory workforce, 104; cotton industry, 100; domestic industry, output growth in, 98; earlier modes of production, 97–98; economies of scale, factories taking advantage of, 110; electrification, 190, 195; Industrial Revolution, 97, 100–101; international trade, rise of, 99; inventions, 102; iron, railroads, and steam, 105–11; mechanical clock as enabling technology for, 47; railroad, arrival of, 108; rise of machines, 99–105; silk industry, beginnings of, 99; social savings of steam engine, 107; steam engine, economic virtuosity of, 107; working class, 98 Fairchild Semiconductor, 359 Fair Labor Standards Act of 1938, 200 farming: disappearance of jobs, 197, 203; mechanization of, 324; revolution, 168–69 feudal oligarchies, replacement of, 58 feudal order: political participation in, 265; rise of, 41, 62 Field, Alexander, 163, 170 Finley, Moses, 36 First Opium War, 88 Fisher, Alva J., 27 Fisher, Irving, 210 Ford, Henry, 141, 148, 167, 195, 365 Ford assembly lines, 18, 365 Ford Motor Company, 148, 199, 240 France, industrial development in, 84 Francis I, Holy Roman Emperor, 85 French Revolution, 90 Friedman, Milton, 355 Friedman, Thomas, 257 Fukuyama, Francis, 141, 264–65, 273, 343 Furman, Jason, 322 Galileo, 39, 52, 54, 94 Galor, Oded, 133 Gans, Joshua, 308 Garden of Eden, 191 Gaskell, Elizabeth, 117 Gaskell, Peter, 117–119, 135, 229, 249 Gates, Bill, 10 Gates paradox, 10, 11, 21 General Electric, 155, 157, 215, 289 General Motors assembly lines, 18 geography of new jobs, 256–63 George Washington Bridge, 167 Giffen, Robert, 132–33 gig mill, 10, 76, 86, 128 Gilded Age, 208 Gille, Bertrand, 39–40 Gini coefficient, 209, 245 Gladstone, William Ewart, 133 Glaeser, Edward, 257, 261, 263 globalization: automation, and populism, 277–85; backlash against, 365; clamping down on, 290; costs of, 366; facilitator of, 282; first wave of, 171; losers to, 21, 26; vanishing jobs and, 11 Glorious Revolution of 1688–89, 79, 82–83, 86 Golden Gate, 167 golden postwar years, 239 Goldfarb, Avi, 308 Goldin, Claudia, 213, 349 Goldin, Ian, 357 Gompers, Samuel, 279 Goodyear Tire, 199 Google, 305 Google Translate, 304 Goolsbee, Austan, 340 Gordon, Robert, 198, 202, 220, 272, 342 government regulations, 49, 137 Great Depression, 13, 143, 170, 211, 272 Great Divergence, 24; absence of economic revolution, 95; beginnings of industrialization, 94; factory system, evolution of (see factory system); Industrial Revolution (see Industrial Revolution); per capita income growth, 94; rise of the machines, 93; textile industry, Industrial Revolution begun in, 95 Great Escape, 8 “great exception” in American political history, 200 Great Migration, 205 Great Recession, 244, 284, 339, 343 Green, William, 174 Greif, Avner, 88, 92, 344 growth, culture of, 77 Gutenberg, Johannes, 47 Habsburg Empire, 85 Hammer, Michael, 326 Hansen, Alvin, 179, 342 Hargreaves, James, 102–3 Harlem, 1 Harper, Kyle, 37 Hawking, Stephen, 36 hazardous jobs, end of, 195, 198 health conditions, during Industrial Revolution, 114–15 Heaton, Herbert, 37 Heckman, James, 351 Heilbroner, Robert, 335 Hellenism, technological creativity of, 39 Henderson, Rebecca, 305, 331 Hero of Alexandria, 39 high school graduates, employment opportunities for, 237 high school movement (1910–40), 214 Himmelfarb, Gertrude, 268 Hindenburg disaster, 110 hinterland, cheap labor and housing of, 261 history deniers, 23 Hitler, Adolf, 12 Hobbes, Thomas, 8, 46 Hobsbawm, Eric, 7 Hoover, Herbert, 211 horseless age, 164 horse technology, 43, 163 Hounshell, David, 148, 150 household revolution, 155–56 housing, zoning and, 361–62 housing bubble, 282 human capital accumulation, indicators of, 133–34 Humphries, Jane, 103, 121 Hurst, Erik, 338 Huskisson, William, 109–10 Hyperloop, 363 IBM, 231 Ibsen, Henrik, 17 Ice Age, 64, 76 identity politics, 278 “idiocy of rural life,” 62–64 income(s): disparities of, 61; reshuffling of, 287 income tax (Britain), introduction of, 133 incubators, nursery cities serving as, 261 industrial bourgeoisie, 267 industrial capitalism, rise of, 218 industrial centers, rise of, 115 industrial espionage, 6 industrialization, first episode of, 16 industrial organization, fundamental principle of, 229 Industrial Revolution, 68, 70; alcoholism, 123; in Britain, 329; Britain’s edge during, 19; British income tax, introduction of, 133; capital share of income, 131–32; child labor, 123, 134; children as robots of, 8–9; classic years of, 113; closing decades of, 138, 266; conditions of England question, 116–25; consumer revolution preceding, 68; cotton yarn manufacturing at dawn of, 100–101; divergence between output and wages, 131; domestic system, description of, 118; economic consequences of, 17; Engels’ pause, 131–37; engine of, 73; Englishmen left off worse by, 364; factories existing before, 94; gig mills, 128; golden age of industry, 118; government regulation, 137; hand-loom weaver, as tragic hero of Industrial Revolution, 121; health conditions, 114–15; human capital accumulation, indicators of, 133–34; labor income share captured, 114; industrial centers, rise of, 115; jobs created by, 16; key drivers of, 342; labor unions, bargaining power of, 137; Lancashire riots, 125, 127; leading figures of, 70; literacy rates, 134; Luddites, 125–31; machinery question, concerns over, 116; machinery riots, 127, 130; macroeconomic impact of, 94; material living conditions, decline of, 114, 120–21; mobility of workers, 122; obsolescence of worker skills, 124; origins of, 6, 80–91; political situation of workers, 129; reason for beginnings in Britain, 75; recipients of the gains of, 113; standard of living issue, 121; steam power, impact of on aggregate growth, 136; symbolic beginning of, 97; tax revenue, 133; technical change during closing decades, 139; technological progress, attitudes toward, 112; trajectory of inequality in Britain during, 217; true beginnings of, 100; unemployment, 113, 117, 125; victims of, 9; Victorian Age, machinery critics of, 119; wave of gadgets, 330; working poor, 113 inequality: age of, beginnings of, 62; Neolithic rise in, 63 inflation, 294 information technology, first revolution in, 47 inner-city ghettos, problems in, 258 innovation, 257; nurseries for, 261 innovation gap, 352 in-person service jobs, 235 inspiration without perspiration, 51–59 installment credit, 159, 167 institutional divergence (colonial Europe), 81 Intel, 359 interchangeable parts: concept of, 149; pioneering of, 74 International Labour Organization (ILO), 181 International Monetary Fund (IMF), 245 international trade, rise of, 67, 69, 99 Internet of things, 22 internet traffic: spread of, 328; worldwide, 303 inventions: agriculture, 54, 62; assembly line, 141, 365; barometer, 52, 59; bicycle, 165; camel saddle, 77; carding machine, 102; of classical times, 39; coke smelting, 108; electric starter, 166; iron, 36; light bulb, 2; mariner’s compass, 50; movable-type printing press, 47; nailed horseshoe, 43; navigable submarine, 52; personal computer (PC), 231; power loom, 105; spinning jenny, 102; steam digester, 55; steam engine, 52, 76; stirrup, 43; stocking-frame knitting machine, 54, 76; submarine, 73; telescope, 59; transistor, 231; typewriter, 161–62; washing machine, 27; water frame, 102; waterwheel, 38; wheel, 35 Iron Age, 35 iron laws of economics, 206 James I of England, King, 52 Japan, ascent of, 289 JD. com, 313 Jeffersonian individualism, 200 Jenkinson, Robert, 2nd Earl of Liverpool, 130, 289 Jerome, Harry, 13, 154, 198, 328 job demand, creation of, 262 Johnson, Lyndon, 184 Joyce, James, 16 Kaldor, Nicholas, 5, 205 Kasparov, Garry, 301 Katz, Lawrence, 135, 213, 245, 349 Kay-Shuttleworth, James, 117, 229 Kennedy, John F., 183 Kettering, Charles, 166 Keynes, John Maynard, 332, 334 King, Gregory, 68 knowledge work, 235, 259 Komlos, John, 115 Korea, ascent of, 289 Korean War, 180 Krugman, Paul, 12 Kuznets, Simon, 5, 206–7 Kuznets curve, 207, 212 labor, division of, 228 labor multiplier, 347 Labor Party, rise of, 268 labor productivity, gap between worker compensation and, 244 labor unions, 212; bargaining power of, 201, 277; legalization in Britain, 190 laissez-faire regime, 25, 267 lamplighters, 1–2 Lancashire riots of 1779, 90 landed aristocracy, 83 Landes, David, 9, 112, 118, 134, 343 Land-Grant College Act of 1862, 364 Latin Church, oppression of science by, 79 laundress, vanishing of, 27, 160 Lee, William, 10, 54 Lefebvre des Noëttes, Richard, 43 Leonardo da Vinci, 38, 51, 73 Leontief, Wassily, 20, 338, 343 Levy, Frank, 237, 302, 323 liberal democracy, components of, 267 Lindert, Peter, 61, 68, 114, 207, 211, 269, 271 literacy, demand for, 76 Liverpool-Manchester Railway, 109 lobbying, corporate spending on, 275 Locke, John, 83 Lombe, John, 52, 99–100 Lombe, Thomas, 6, 100 London Steam Carriage, 109 longshoremen, vanishing of, 172 Louis XIV of France, King, 84 Luddites, 9, 18, 125–31, 341; imprisoned, 20; new, 286–92; riots, 89, 92; uprisings, 265 machinery question, 116, 174–88; adjustment problems, 177; automation, employment effects of, 180; computers, automation anxiety concerning, 183; elevator operators, 181–82; musicians, displaced, 177–78 machinery riots, 9, 265, 289; absence of (America), 190; Britain, 90 Maddison, Angus, 66 Magellan, Ferdinand, 51, 67 majority-rule voting system, 270 Malthus, Thomas Robert, 4, 64, 73, 316, 345 Malthusian logic, 345 Malthusian trap, escape of, 65 Manhattan Project, 74 Manpower Training and Development Act (MDTA), 353 Mantoux, Paul, 97, 101, 126 Manufacture des Gobelins, 84 Manufacture Royale de Glaces de Miroirs, 84 manufacturing: blue-collar jobs, disappearance of, 251, 254; American system of manufacturing, pioneers of, 149; factory electrification, 151–55; interchangeable parts, concept of, 149 Margo, Robert, 135, 145 markets, integration of, 86 Marx, Karl, 26, 47, 98, 239, 364 Massey, Douglas, 256 Massive Open Online Courses (MOOCs), 354 mass production, 147–73; American system of manufacturing, pioneers of, 149; containerization, 171–72; direct drive, 153; factory electrification, 151–55; horseless age, 164; household revolution, 156; industries, 18; installment credit, 159, 167; interchangeable parts, concept of, 149; Model T, 167; unit drive, 153 Maurice of Nassau, Prince of Orange, 59 Maybach, Wilhelm, 166 McAfee, Andrew, 303, 339 McCloskey, Deirdre, 70 McCormick, Cyrus, 149, 168 McLean, Malcom, 171 mechanics, Galileo’s theory of, 53 mechanization, age of automation vs. age of, 227 median voter theories, 270 medieval Christianity, 78 mercantilism, flawed doctrine of, 83 Mesopotamia, 35 metals, discovery and exploitation of, 35 Michigan Antitrust Reform Act of 1985, 359 Microsoft, 306 Middle Ages: agricultural technology in, 42; feudal order of, 57; onset of, 41; technical advances of, 50; traditional crafts of, 68 middle class, descent of, 223–25; artificial intelligence, 228; automation, adverse consequences of, 240; cognitive divide, 238–43; computer-controlled machines, jobs eliminated by, 228; computers, 228–38; corporate profits, 244; division of labor between human and machine, 228; earnings gap, 230; Engels’ pause, return of, 243–48; golden postwar years, 239; Great Recession, 244; high school graduates, employment opportunities for, 237; industrial organization, fundamental principle of, 229; in-person service jobs, 235; knowledge workers, 235; labor productivity, gap between worker compensation and, 244; mechanization, age of automation vs. age of, 227; multipurpose robots, 242; rule-based logic, 228; Second Industrial Revolution, elimination of jobs created for machine operators during, 228; “symbolic analysts,” 235 middle class, triumph of, 218–222; agriculture, mechanization of, 189; automotive industry, 202; baby boom, 221; blue-collar Americans, unprecedented wages of, 220; child labor, as opportunity cost to education, 214; collective bargaining, 192; corporate giants, 208; corporate paternalism, 200; education and technology, race between, 216; end of drudgery, 193–98; Engels’ pause, 219; factory electrification, 190, 195; farming jobs, decline of, 197, 203; Great Depression, 211; “great exception” in American political history, 200; Great Migration, 205; hazardous jobs, end of, 195, 198; high school movement (1910–40), 214; Jeffersonian individualism, 200; Kuznets curve, 207, 212; labor unions, 201, 212; leveling of American wages, 211; machinery riots, absence of, 190; middle class, emergence of, 192, 292; national minimum wage, introduction of, 211; new consumer goods, Americans’ growing appetite for, 203; New Deal, 200, 212; public schooling, 214; Second Industrial Revolution, 209, 217; skill-biased technological change, 213; tractor use, expansion of, 196; urban-rural wage gap, 209; Wall Street, depression suffered by, 211; welfare capitalism, 198, 200; welfare state, rise of, 221; white-collar employment, 197, 218 Middle East, 77 Milanovic, Branko, 217, 245 mining, 194, 197 Minoan civilization, 34 mobile robotics, 342 mobility, demands for, 348 mobility vouchers, 360 Model T, 167 modern medicine, rise of, 22 Mokyr, Joel, 19, 52, 76–77, 79 Moore’s Law, 107, 301, 304 Moravec’s paradox, 236 Moretti, Enrico, 258, 262–63, 360 Morgan, J.

…

Some of the noblest exertions of the human mind have been set in motion by the necessity of satisfying the wants of the body.”3 A number of examples of technological developments since the Industrial Revolution that conform to this view spring to mind, including the Manhattan Project, set up by the U.S. government to develop an atomic bomb before Nazi Germany could do so; the steam engine developed by Thomas Savery to pump water out of British coal mines; and the interchangeable parts pioneered by Eli Whitney to “substitute correct and effective operations of machinery for the skill of the artist which is acquired only by long practice and experience; a species of skill which is not possessed in this country to any considerable extent.”4 To return to the preindustrial world, most demand-driven explanations of the lack of preindustrial growth tend to emphasize the fact that labor-saving technologies, which allow us to produce more with less, make economic sense only if capital is relatively cheap compared to labor.

Power and Progress: Our Thousand-Year Struggle Over Technology and Prosperity

by

Daron Acemoglu

and

Simon Johnson

Published 15 May 2023

The gains were evident to the British Parliamentary Committee inspecting American arms factories using interchangeable parts: “The workman whose business it is to ‘assemble’ or set up the arms, takes the different parts promiscuously from a row of boxes, and uses nothing but the turnscrew to put the musket together, excepting on the slott, which contains the bandsprings, which have to be squared out at one end with a small chisel.” This was not a deskilling technology, however. A former superintendent at Samuel Colt’s armory noted that interchangeable parts reduced labor requirements by “about 50 per cent” but required “first-class labour and the highest price is paid for it.”

…

The company that manufacturer Nathaniel Wheeler formed with inventor Allen B. Wilson started out producing fewer than 800 machines in 1853 using traditional handcraft methods. By the 1870s, it had introduced interchangeable parts and new specialized machine tools, and its annual output exceeded 170,000 units. Soon the Singer sewing machine company went further, combining interchangeable parts, specialized machinery, and better designs, and was producing more than 500,000 units per year. Woodworking and then bicycles were the next industries to be transformed by the American System of Manufacturing.

…

Levasseur, a Frenchman visiting American steel mills, silk factories, and packinghouses, put it in 1897, “The inventive genius of the American is perhaps a native gift, but it has been unquestionably stimulated by the high rate of wages. For, the entrepreneur seeks to economize human labor the more it costs him. On the other hand, when machinery gives greater productive force to the laborer it is possible to pay him more.” This was one outcome of Eli Whitney’s focus on interchangeable parts, which strove to build standard pieces that could be combined in different ways, making it easier for unskilled workers to produce guns. Whitney himself described his objective as “to substitute correct and effective operations of machinery for that skill of the artist which is acquired only by long practice and experience; a species of skill which is not possessed in this country to any considerable extent.”

About Time: A History of Civilization in Twelve Clocks

by

David Rooney

Published 16 Aug 2021

Brown, was formerly a clock- and watchmaker and, in the opinion of one engineer who trained in Brown & Sharpe’s machine shops in the 1870s: deserved greater credit than any other man for developing and making possible the great accuracy and the high efficiency of modern machine practice and in making it possible to manufacture interchangeable parts . . . I know of none who deserves a higher place than, or who has done so much for the modern high standards of American manufacturers of interchangeable parts as[,] Joseph R. Brown.17 That engineer was Henry Leland, founder of Cadillac, who introduced interchangeable parts to the automotive industry. With the mass production of the later nineteenth century came mass consumption, and mass marketing sold the products of manufacturing to an ever wider public.

…

The American System, as the world came to know it, took two ideas—standardized, interchangeable parts, and the use of special-purpose machine tools to replace skilled human labor—and unlocked the door for repeatable mass production of complex products as diverse as guns, sewing machines and typewriters. But for this new world of mass production to grow and flourish, a new breed of heavy, highly precise specialist machine tools would be needed. The development of American machine tools in the 1860s and 1870s, suitable for widespread use in manufacturing high-precision and interchangeable parts, followed a similar pattern to the British developments exactly a century earlier which brought the factory system into existence and kick-started an industrial revolution.

Arriving Today: From Factory to Front Door -- Why Everything Has Changed About How and What We Buy

by

Christopher Mims

Published 13 Sep 2021

Along with clocks and pocket watches produced by the same company, they were among the first widely available timekeeping devices in the world to be made from interchangeable parts. By the 1870s, stopwatches were common at horse races and sporting events, and they were also used in the military to time artillery shots. But it was Taylor and his disciples who would bring these instruments into the factory. Mass production and interchangeable parts made these devices widely available and also eventually drove universal adoption of the system of scientific management. In later years, scientific management would come to be so closely identified with the stopwatch that men in suits skulking about factory floors, stopwatches and notebooks in hand, were treated with open hostility by some workers.

…

Steel’s unique properties mean it can be cast into any shape, then machined to incredibly fine tolerances. Steel tools and steel measuring devices in the hands of skilled and obsessive craftsmen could yield truly interchangeable—and durable—parts. Interchangeable parts could then be produced in massive quantities. Eventually, Henry Ford borrowed the idea of the conveyor belt from slaughterhouses, where carcasses were carried from one worker to the next on overhead hooks, and married it to the system of interchangeable parts he had already borrowed from other automakers. On October 7, 1913, Henry Ford’s first assembly line clattered to life in the company’s urban Highland Park, Michigan, factory.

…

When Taylor entered the machine shop, a transition was underway in which managers of variable backgrounds were being replaced by engineers granted the responsibilities of management. Engineering itself was just becoming an accredited profession, and as the scientific method was applied to the products of engineering, so too were engineers primed to apply it to the management of the humans who worked with machines. In an age in which the use of interchangeable parts was not yet universal and the assembly line was just getting started—that is, the age before Ford’s system of mass production had taken over the world—it was often the case that every complicated machine was different from every other and had to be constructed by hand. The speed at which people worked was the biggest bottleneck to productivity and revenue.

Cheap: The High Cost of Discount Culture

by

Ellen Ruppel Shell

Published 2 Jul 2009

A tireless self-promoter, he managed to take and get credit for being the first to mechanize gun manufacture through the use of interchangeable parts, a distinction for which he is known to this day. Unfortunately for schoolchildren everywhere, this distinction was unearned. As one scholar put it, “Except for Whitney’s ability to sell an undeveloped idea, little remains of his title as father of mass production.” The real hero here was Simeon North, a steady and humble maker of scythes and other small agricultural implements who pioneered both interchangeable parts and its corollary, mass production. Using a manufacturing technique that would later be linked to efficiency expert Frederick Winslow Taylor, North broke down the gun-building process into a series of basic tasks and distributed the work among a group of semiskilled laborers.

…

North not only fulfilled the terms of his contract within his deadline, but was awarded another one to produce an additional twenty thousand pistols, the components of which were “to correspond so exactly that any limb or part of one pistol may be fitted to any other pistol of the twenty thousand.” The first contract known to stipulate interchangeable parts, it was a resounding step in the inexorable march toward low price. WHITNEY’S FAMOUS GIN, though not the font of mass production he claimed, nonetheless played a critical role in lowering the price of textiles. The gin separated cotton fiber from seed, cleaning more cotton in minutes than a battalion of humans could in a day.

…

“Old Man,” high/low pricing Hitchcock, Alfred H & M home construction Home Depot Home Shopping Network Homo economicus economic model hotel industry Hounshell, David Household Registration Law (China) Hu Jindou Hull, Brent Humphrey-Hawkins Act Humpty Dumpty hyperbolic time discounting IKEA advertising by alliances with not-for-profits bookcase catalog designing to price de-skilling of labor flat packing forestry industry and number and location of stores suppliers to illusion of objectivity imports Chinese (See China) Japanese and Asian, in 1960s, markdowns of shrimp income declines in real income, early 2000s, post-World War II boom years income taxes, under Eisenhower and Kennedy India inelastic goods and services inflation of 1970s, CPI, in 2007-2008, Feds targeting of employment to fight during World War II, Ingka Holding innovation In Search of Excellence (Peters) instant rebates insula interchangeable parts International Herald Tribune inventory management iPhone iPod Ireland Irish potato famine “Is This the Worlds Cheapest Dress . . .” (Wilson) J. C. Penney Japanese imports John Wanamaker & Co. Jones, Lee Jonze, Spike Jordan, Julie Journal of Economic Behavior and Organization Journal of the Academy of Marketing Science just-in-time distribution K.

Behemoth: A History of the Factory and the Making of the Modern World

by

Joshua B. Freeman

Published 27 Feb 2018

It was a long road to enable such complicated machinery to be produced on a mass scale. Fordism built on two manufacturing innovations, interchangeable parts and continuous flow. Until the early nineteenth century, products with interacting metal parts, like guns or clocks, were individually made by skilled artisans, who spent a great deal of time fitting together parts, filing and adjusting them to make sure they worked together. No one finished product was exactly like the next. The standardization of parts occurred first in the United States. Generally, introducing interchangeable parts initially increased the cost of production, since it required a huge investment in specialized machines, tools, jigs, and fixtures and a great deal of experimentation to achieve the tolerances that made it possible to assemble a product from a pile of parts without custom fitting.

…

Generally, introducing interchangeable parts initially increased the cost of production, since it required a huge investment in specialized machines, tools, jigs, and fixtures and a great deal of experimentation to achieve the tolerances that made it possible to assemble a product from a pile of parts without custom fitting. The key innovations took place before the Civil War in New England armories. The military greatly valued the ease of repair allowed by interchangeable parts and cared less about costs than private manufacturers. “Armory practice” slowly spread to the making of clocks, sewing machines, typewriters, agricultural equipment, bicycles, and other civilian products.4 American conditions promoted standardization and interchangeability. A mass market existed that justified heavy capital investment and that was hard to take full advantage of without uniformity.

…

In 1855, 400,000 brass clocks were produced in the United States. During the Civil War, three million rifles were used.5 A shortage of skilled workers and relatively high wages made it expensive and sometimes impossible to produce complex products in large quantities using traditional artisanal methods. With interchangeable parts, skilled workers were still needed to build specialized machinery and tooling, but less skilled workers could churn out parts and assemble them.6 None of this was easy to achieve. The Singer Manufacturing Company, one of the most celebrated manufacturers of its day, illustrated the challenge.

Capitalism in America: A History

by

Adrian Wooldridge

and

Alan Greenspan

Published 15 Oct 2018

The new technology spread rapidly across New England: by 1820, 86 firms were using 1,667 power looms while traditional spinning mills in Philadelphia and Rhode Island were forced to shut up shop.10 Production boomed from 4 million yards of cotton cloth a year in 1817 to 308 million twenty years later.11 As well as importing the idea of the factory from Britain, the Yankees pioneered a new system of production—what Europeans called the “American system of production,” and what might better be known as the system of interchangeable parts. In 1798, Eli Whitney was given a gigantic contract for ten thousand muskets from the U.S. government. When it became clear that he could not possibly meet his deadline, he came up with the idea of mass-producing muskets with interchangeable parts. Though his idea was not original—the French had pioneered interchangeable parts for muskets in the 1780s—the Americans took it to a much higher level. In France, the parts were made by craftsmen working with hand tools.

…

Standardization brings two quick benefits: it allows you to boost the productivity of relatively unskilled workers by simplifying once-complicated tasks, and it allows you to reap economies of scale and scope by expanding rapidly. Having established its lead as a manufacturing power in the nineteenth century by taking the principle of interchangeable parts further than European countries, and having then turned itself into the arsenal of democracy by taking the principle of standardization further than anyone else in the production of tanks and ships, America consolidated its position as the world’s most affluent society by taking standardization to new levels in old industries, but also applying it to new areas, such as building houses and serving food.

…

South, 80, 89 1850–2000, 297, 297 1865–1914, 93–94, 95–96, 157, 165 1924–1930, 191–92, 194, 217–18 1930–1970, 285, 297 1970–2000, 345–46 Immigration Act of 1924, 191–92, 436 Immigration and Naturalization Service (INS), 93–94, 297 “implied powers,” 65 imports, 34, 55, 231, 233 U.S., by country of origin (1971–2016), 370, 370–71 U.S., steel, 312, 314–15, 315 incarceration, 398–99 income taxes, 25, 159, 184, 186, 251–52, 268, 329, 427 industrialization, 45–46, 64, 169, 427 Industrial Revolution, 15, 45, 402, 434 industrial unrest, 171–76 industrial vs. agrarian visions of America, 61–68 inequality, 168, 169–70, 295 inflation, 161, 300, 306, 307, 327, 377 information revolution, 16–17, 55=57 infrastructure, 244, 274, 390, 394–95 “installment buying,” 212 “institutional voids,” 132 integrated circuits, 351 integrated national market, development of, 212–16 Intel, 330, 351, 353 intellectual property rights, 8 interchangeable parts, 71–72 interest rates, 42, 235, 236 internal combustion engine, 103–4, 198–99 International Harvester, 144–45 International Monetary Fund (IMF), 229, 278, 377, 382 Internet, 353–56 interstate commerce, 166 Interstate Commerce Act of 1887, 166 Interstate Commerce Commission, 166, 167 interstate system, 286 Iran-Contra affair, 326 Iraq War, 267, 369, 370, 438 IRS (Internal Revenue Service), 259–60, 334 Irving, Washington, 40 isolationism, 187, 230, 343–44 IT revolution, 348–56, 402–3 Jackson, Andrew, 16, 25, 55, 68–69, 157, 267, 415 James, Henry, 182 Japanese management culture, 314, 344–45 Japanese manufacturing, 314, 316–17, 320–21 Jarvis, Howard, 310 Jay, John, 62 jazz, 203, 215 Jazz Singer, The (movie), 194 Jefferson, Thomas, 5, 8, 9, 34, 40, 43, 46, 61–67, 75 Jell-O, 92 Jensen, Michael, 337 Jiang Zemin, 371 job displacement, 21–22 Jobs, Steve, 323–24, 353, 439 Johnson, Andrew, 158 Johnson, George, 208–9 Johnson, Howard, 197 Johnson, Hugh, 255, 256 Johnson, James Weldon, 215 Johnson, Lyndon B., 25, 248, 302, 372 Great Society, 25, 303–5 Johnson & Johnson, 391 Johnson Wax, 320 Jolson, Al, 194 Jordan, Wilbur, 364 Josephson, Matthew, 170 Joule, James Prescott, 104 Journal of Commerce, 16, 55 J.P.

Evil Geniuses: The Unmaking of America: A Recent History

by

Kurt Andersen

Published 14 Sep 2020

The inventor and nail manufacturer Jefferson, who’d been excited for years about the prospect of interchangeable parts, was wildly enthusiastic. Not long after the faked demo, he wrote a letter of introduction on Whitney’s behalf to the governor of Virginia, his protégé James Monroe. Whitney “has invented moulds & machines for making all the pieces of his locks so exactly equal,” the president wrote, and thus “furnishes the US. with muskets, undoubtedly the best they receive.” None of that was true. In fact, Whitney wouldn’t deliver any muskets to the government until 1809, nine years later, and interchangeable parts weren’t perfected until after his death.*1 Whitney was absolutely honest when he admitted in 1812 that the whole point of using identical, interchangeable parts to make things in factories would be to render old-fashioned craftspeople obsolete—that is, “to substitute correct and effective operations of machinery for the skill of the artist.”

…

Eli Whitney also happens to be a fabulous case study of the overenthusiasm and overpromising that surround technological progress—especially at moments of revolutionary economic change, such as the early nineteenth and early twenty-first centuries. We learn in school that Whitney came up with another, more foundational piece of the industrial revolution: manufacturing things out of standardized bits and pieces, interchangeable parts, from gears and levers then to Ethernet plugs and semiconductor chips now. Coming off the success of the cotton gin, young Whitney convinced the new U.S. government that he was their man to mass-produce ten thousand muskets, even though he knew nothing about making guns. Two years later, after failing to meet his contractual deadline, he went to Washington to keep his remorseful buyers on the hook.

…

Two years later, after failing to meet his contractual deadline, he went to Washington to keep his remorseful buyers on the hook. His state-of-the-art musket was taking a bit longer than expected to get right, he told President Adams and President-elect Jefferson and the secretary of war, because it would consist entirely of fantastic new interchangeable parts, meaning that manufacture would be cheaper and faster, and repair easier. He spread a hundred metal pieces on a tabletop. Sirs, here before you are all the ordinary parts from ten of my new gunlocks, he explained. Hand me one of each, any you wish, at random, and from those, using only a screwdriver, I shall assemble a working apparatus!

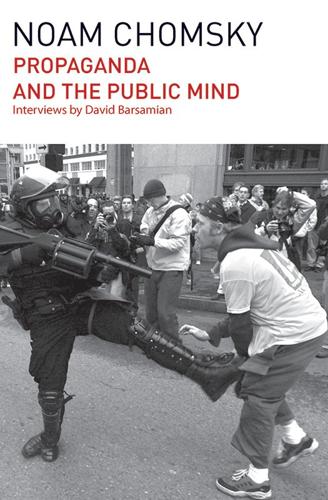

Propaganda and the Public Mind

by

Noam Chomsky

and

David Barsamian

Published 31 Mar 2015

Sometimes that also means for a pregnancy you have to go to a hospital twenty miles away and not the one that’s two miles away. The HMOs are businesses. They’re going to maximize profit. If it turns out that they can do it the way you maximize profit in a factory, by standardization and regulation and interchangeable parts, and treating people like interchangeable parts in a machine, of course they’ll do that. Also, the HMOs have quite high costs, naturally. They’re private businesses. A lot of the money goes into things like advertising, overhead, and layer after layer of micromanagement. You have to manage the doctors. If a doctor wants to do something, he’s got to get approval from what the right likes to call “pointy-headed bureaucrats,” though the term is used only for government.

…

But to talk about the U.S. model as being one of rugged individualism and entrepreneurial skills, kept away from state interference —again, it’s hard to find words to describe it. Incidentally, this goes back to the origins of U.S. history. Take the American system of mass production, of manufacturing, the big new system in the nineteenth century. The basic ideas of that were worked out in places like the Springfield Armory, where they needed interchangeable parts and careful quality control. Then it was transferred into the private sector. In fact, the Reagan administration went far beyond just protecting American industry and pouring public funds into advanced technology. It also had to overcome U.S. management failures. In the 1970s, there was a lot of concern that incompetent management meant the United States was falling behind the Japanese particularly, but the Europeans, too.

A World Without Email: Reimagining Work in an Age of Communication Overload

by

Cal Newport

Published 2 Mar 2021

The factories deploying this “craft method,” as it became known, were directly scaling up the same natural approach Karl Benz had used to assemble the first practical automobile in the late 1800s.2 After working his way from the Model A, which seated only two and cost extra if you wanted a roof, through Models B, C, F, K, and N, Ford finally arrived in 1908 at what would become his masterpiece of pragmatic conveyance: the Model T. With this new design, Ford set out to innovate not just the features of the vehicle but also the entire process by which it was constructed. The first major step in this innovation was the introduction of interchangeable parts. Drawing from techniques that had emerged originally from New England armories around the time of the Civil War, Ford reinvested profits from the early versions of this popular vehicle to engineer specialized tools that could produce car parts with enough precision to eliminate the lengthy process of filing and grinding otherwise needed to get these parts to fit together.3 As the company boasted: “You might travel around the world in a Model T and exchange crankshafts with any other Model T you met en route, and both engines would work as perfectly after the exchange as before.”4 By eliminating grinding, interchangeable parts made faster assembly feasible, but Ford still had to figure out how to get the roughly one hundred precisely engineered pieces that made up a Model T to come together into a working automobile in the shortest amount of time possible.

…

Drawing from techniques that had emerged originally from New England armories around the time of the Civil War, Ford reinvested profits from the early versions of this popular vehicle to engineer specialized tools that could produce car parts with enough precision to eliminate the lengthy process of filing and grinding otherwise needed to get these parts to fit together.3 As the company boasted: “You might travel around the world in a Model T and exchange crankshafts with any other Model T you met en route, and both engines would work as perfectly after the exchange as before.”4 By eliminating grinding, interchangeable parts made faster assembly feasible, but Ford still had to figure out how to get the roughly one hundred precisely engineered pieces that made up a Model T to come together into a working automobile in the shortest amount of time possible. To accomplish this goal, he tried out many different ideas.

…

In reality, however, the pieces of the lowly Model T were manufactured with considerably more exactitude—the high price of the Rolls-Royce afforded its manufacturer the labor required to hand-adjust looser parts into a tight fit. 4. Freeman, Behemoth, 123. 5. As Simon Winchester points out, American armories had geared up mass production lines years earlier. By 1913, sewing machine, bicycle, and typewriter manufacturers had also begun taking advantage of the interchangeable parts revolution to experiment with fast-moving assembly lines. Ford claims, however, that his main inspiration was actually the disassembly of animal carcasses that he had witnessed at the nearby Chicago meatpacking plants, where the knife-wielding meatpackers stood in place while the animals moved by, hanging from chains. 6.

Now I Sit Me Down: From Klismos to Plastic Chair: A Natural History

by

Witold Rybczynski

Published 22 Aug 2016

Even so, soon additional factories were needed and three were built in Moravia as well as a fifth in Hungary. No. 14 café chair (Michael Thonet) The cover of the first Thonet catalog, published in 1859, carried the proud motto Beigen oder Brechen, To Bend or to Break. The broadsheet illustrated twenty-six products: chairs, settees, and tables. The chairs were designed with interchangeable parts, so that different models could be created by recombining assorted backs and arms. Number 14, a café chair, was the least expensive item; it sold for three Austrian florins, about the price of a bottle of good wine. Known as the Konsumstuhl, or Consumer’s Chair, No. 14 was the workhorse of the Thonet line.

…

Photographs of him in later life show a handsome man with longish hair and a full white beard; he resembles Karl Marx, another Rhineland Palatinate native. The resemblance ends there, for Thonet was an early example of the capitalist-entrepreneur. Fifty years before Henry Ford introduced the Model T automobile assembly line in Highland Park, Thonet had already put in place the basic elements of mass production: division of labor, interchangeable parts, mechanization. As Ford would later do, he integrated his business vertically, buying forest land, laying railroad track, operating his own sawmills, and building his own machine saws, steam retorts, and iron molds. He even manufactured the bricks that were used to build the worker housing, schools, and libraries in his company towns.

The Computer Boys Take Over: Computers, Programmers, and the Politics of Technical Expertise

by

Nathan L. Ensmenger

Published 31 Jul 2010

The explicit goal of testing programs at large employers like SDC was to reduce the overall level of skill among the programming workforce. By identifying the minimum level of aptitude required to be a competent programmer, SDC could reduce its dependence on individual programmers. It could construct a software factory out of the interchangeable parts produced by the impersonal and industrial processes of its aptitude test regimes. It is this last consequence of aptitude testing that is the most interesting and perplexing. Like all of the proposed solutions to the labor shortage in programming, aptitude testing also embodied certain assumptions about the nature of the underlying problem.

…

There is no single development, in either technology or in management technique, that by itself promises even one order-of-magnitude improvement in productivity, in reliability, in simplicity.54 Brook’s article provoked an immediate reaction, both positive and negative. The object-oriented programming (OOP) advocate Brad Cox insisted, for example, in his aptly titled “There Is a Silver Bullet,” that new techniques in OOP promised to bring about “a software industrial revolution based on reusable and interchangeable parts that will alter the software universe as surely as the industrial revolution changed manufacturing.”55 Whatever they might have believed about the possibility of such a silver bullet being developed in the future, though, most programmers and managers agreed that none existed in the present.

…

As early as 1962, in a RAND Corporation Symposium on Programming Languages, Jack Little lamented the tendency of manufacturers to design languages “for use by some sub-human species in order to get around training and having good programmers.”63 When the Department of Defense proposed ADA as a solution to yet another outbreak of the software crisis, it was trumpeted as a means of “replacing the idiosyncratic ‘artistic’ ethos that has long governed software writing with a more efficient, cost-effective engineering mind-set.”64 As was mentioned earlier, object-oriented programming enthusiasts advocate for “a software industrial revolution based on reusable and interchangeable parts that will alter the software universe as surely as the industrial revolution changed manufacturing.”65 Once again, the desirability of such a revolution, and its attendant implications for the character and quality of programming labor, is not universally recognized; witness the recent debate about outsourcing, which ties the history of the software crisis into a much larger and longer-running one about globalism, job protection, workers’ rights, and national identity.

A History of the World in 6 Glasses

by

Tom Standage

Published 1 Jan 2005

The British industrial approach was to divide up the manufacturing process into several stages, passing each item from one stage to the next, and using laborsaving machines where possible. The American approach went even farther by separating manufacturing from assembly. Specialized machines were used to crank out large numbers of interchangeable parts, which were then assembled into finished products. This approach became known as the American system of manufactures, starting with guns, and then applied to sewing machines, bicycles, cars, and other products. It was the foundation of America's industrial might, since it made possible the mass production and mass marketing of consumer goods, which quickly became an integral part of the American way of life.

…